The Elegance of Precision: Exploring Stainless Steel Dairy Bends and Tees

Introduction:In the world of stainless steel fittings, precision and hygiene are paramount, especially in industries like dairy where the highest standards are non-negotiable. Two indispensable components that play a crucial role in maintaining the integrity of dairy systems are stainless steel dairy bends and stainless steel dairy tees.The Significance of Stainless Steel:Stainless steel is the material of choice in dairy applications for several reasons. Its corrosion resistance, durability, and ease of cleaning make it the perfect candidate for maintaining the purity of dairy products. Stainless steel is inherently resistant to rust and corrosion, ensuring that the fittings maintain their structural integrity even in demanding environments.Stainless Steel Dairy Bends:

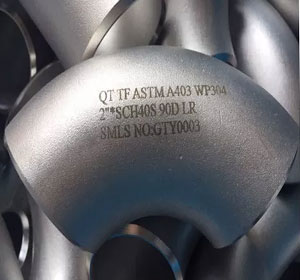

Precision Engineering: Stainless steel dairy bends are designed with precision engineering to ensure optimal fluid flow within dairy processing systems. The smooth, crevice-free surfaces of these bends prevent the accumulation of bacteria and contaminants, upholding the highest hygiene standards.

Versatility: These bends come in various angles, allowing for flexibility in designing dairy pipelines. Whether a subtle 45-degree bend or a sharper 90-degree turn is required, stainless steel dairy bends provide the versatility needed to create efficient and space-conscious systems.Ease of Installation: The fabrication of stainless steel dairy bends is done with ease of installation in mind. Flanged, threaded, or welded connections make these bends adaptable to different installation requirements, ensuring a seamless integration into dairy processing plants.

Stainless Steel Dairy Tees:

Stainless Steel Dairy Tees:Branching Excellence: Stainless steel dairy tee are designed to facilitate the branching of pipelines without compromising the flow or hygiene. The precision in the design of tees ensures that there is minimal turbulence in the flow of dairy products, preventing any build-up or contamination risks.Hygienic Design: Maintaining hygiene is paramount in dairy processes. Stainless steel dairy tees, with their smooth surfaces and sanitary design, contribute significantly to the prevention of bacterial growth and the accumulation of unwanted particles. This is crucial for ensuring the quality and safety of dairy products.Material Integrity: The material integrity of stainless steel dairy tees ensures they can withstand the rigorous cleaning processes that are routine in dairy plants. Their resistance to corrosion and staining makes them easy to maintain, further emphasizing their suitability for the dairy industry.

TAGS :

RECOMMENDED FOR YOU

Best Presale Crypto Launchpad Pays Your Travels

June 18, 2025

Top Signs of a Trustworthy Vehicle Shipping Company

June 17, 2025