How experienced are kurti manufacturers with international buyers?

February 7, 2026

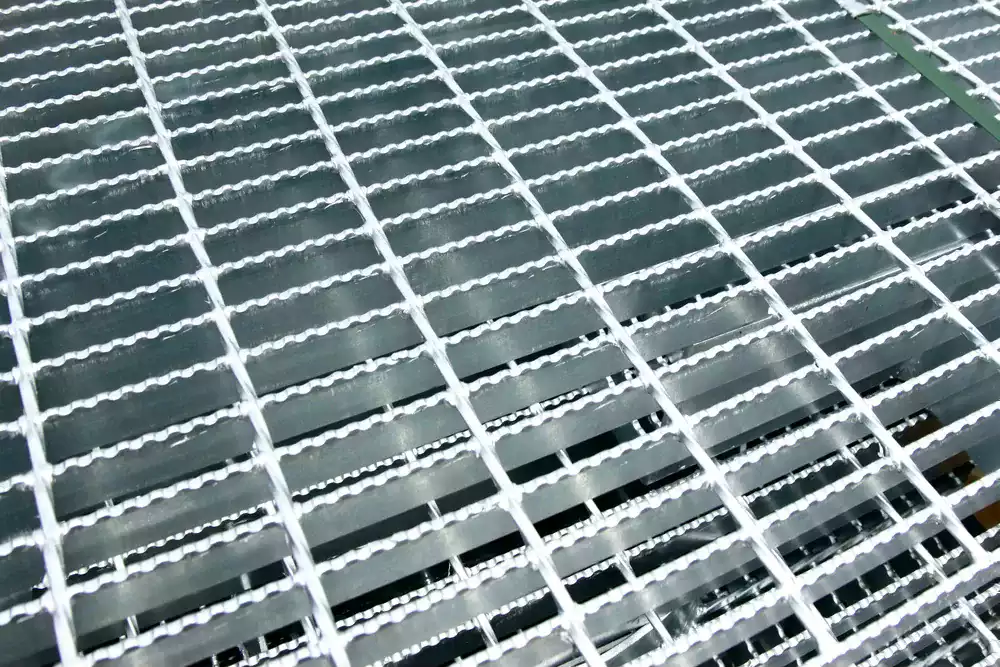

Steel grating is a versatile material widely used in industrial, commercial, and architectural applications. Its durability, strength, and open design make it ideal for walkways, platforms, drainage covers, and other load-bearing structures. However, the performance and longevity of steel grating heavily depend on the type of coatings or finishes applied. In this article, we will explore how different coatings or finishes impact steel grating, while also touching upon related materials like stainless steel tube, which is often used alongside steel grating in construction and fabrication projects.

Hot-dip galvanization is one of the most common finishes for steel grating. This process involves immersing the grating in molten zinc, forming a protective layer that prevents rust and corrosion. Galvanized steel grating performs exceptionally well in outdoor or humid environments, such as chemical plants, marine docks, and wastewater treatment facilities. The zinc coating acts as a barrier, reducing the risk of corrosion from moisture, salt, or other environmental factors.

Using galvanized steel grating increases the lifespan of the structure and reduces maintenance costs. However, galvanization may slightly alter the grating’s appearance with a dull silver finish, which some architects may find less visually appealing. In applications where aesthetics matter, additional coatings or finishing treatments may be necessary.

Painting or powder coating steel grating provides both protective and decorative benefits. Powder coating, in particular, creates a thick, uniform layer that resists scratches, corrosion, and UV damage. Painted or powder-coated grating is ideal for environments where visual appeal is important, such as public walkways, commercial spaces, or decorative stair treads.

The coating also provides flexibility in color selection, allowing designers to match steel grating with other elements, like stainless steel tube railings or supporting frameworks. However, painted coatings can chip or peel over time, especially in high-traffic or industrial areas, which may require touch-ups or periodic maintenance to ensure continued protection.

Although technically a different material than standard carbon steel grating, stainless steel grating deserves mention due to its inherent corrosion resistance. Stainless steel contains chromium, which forms a self-healing oxide layer on the surface. This natural protective barrier prevents rust even in highly corrosive environments, such as coastal areas or chemical processing facilities.

Stainless steel grating is often used in conjunction with stainless steel tube components for handrails, ladders, or structural supports. Its long-term durability eliminates the need for additional coatings in most applications. While the upfront cost is higher than galvanized or painted steel grating, stainless steel reduces maintenance and replacement costs over time.

Zinc plating, or electroplating, is another method to protect steel grating from corrosion. Unlike hot-dip galvanization, electroplating applies a thin layer of zinc through an electrical process. Zinc-plated grating offers good corrosion resistance in less aggressive environments, such as indoor facilities or light-duty outdoor installations.

While this finish is more economical and provides a cleaner look than hot-dip galvanization, the thin zinc layer may wear off faster under heavy loads or abrasive conditions. Therefore, zinc-plated steel grating is suitable for applications where moderate protection is sufficient, and cost is a significant consideration.

Certain coatings focus not only on corrosion resistance but also on improving safety. Anti-slip coatings, often made of epoxy or polyurethane, are applied to steel grating to enhance traction. This is particularly important in industrial plants, chemical facilities, or wet environments where slip hazards are high.

Applying anti-slip finishes on steel grating increases the safety of walkways and platforms while preserving structural integrity. When combined with stainless steel tube supports, the entire system becomes both durable and secure, ideal for demanding work environments.

Some steel grating is coated with aluminum or an aluminum-zinc alloy to achieve lightweight corrosion protection. These coatings combine the strength of steel with the lightweight and reflective properties of aluminum, providing resistance against UV radiation and oxidation. This type of finish is particularly popular in outdoor applications where long-term exposure to sunlight and moisture is expected.

Choosing the right coating or finish for steel grating depends on several factors, including environmental exposure, load requirements, aesthetic preferences, and budget. Galvanized or stainless steel grating is ideal for harsh outdoor environments, while painted or powder-coated finishes work well in visually sensitive areas. Anti-slip coatings improve safety in high-traffic locations, and aluminum-based coatings offer lightweight durability.

It’s also important to consider the compatibility of coatings with other materials. For instance, when steel grating is installed alongside stainless steel tube supports or handrails, using a compatible finish helps prevent galvanic corrosion and ensures long-term performance.

Different coatings and finishes significantly affect the performance, durability, and appearance of steel grating. From galvanized and painted options to stainless steel and anti-slip treatments, each type provides unique advantages depending on the application. Understanding these effects allows engineers, architects, and contractors to select the most suitable grating solution for their projects. By choosing the right combination of materials and finishes, you can enhance the lifespan, safety, and aesthetic appeal of steel grating installations, ensuring optimal performance in any environment.

TAGS : steel grating

February 7, 2026

February 4, 2026

February 4, 2026

February 4, 2026

February 4, 2026