July 14, 2023

What Are The Key Factors To Consider When Selecting Heat Exchanger Tubes?

1.3k0

Factors To Consider In Heat Exchanger Tube Selection

Material Selection

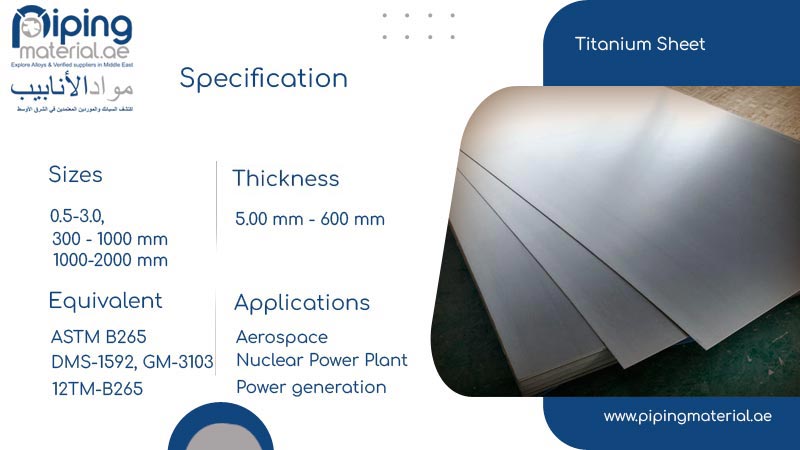

The choice of material for heat exchanger tubes is crucial, as it directly affects their performance and durability. Different applications demand different materials based on factors such as temperature, pressure, fluid composition, and operating environment. Common materials used for heat exchanger tubes include stainless steel, carbon steel, copper alloys, and titanium. Stainless steel is popular due to its excellent corrosion resistance and mechanical properties. Copper alloys offer high thermal conductivity, making them suitable for heat transfer applications. Titanium is known for its exceptional corrosion resistance, particularly in aggressive environments.Tube Size and Dimensions

Proper tube size and dimensions are critical for efficient heat transfer and overall system performance. The tube diameter, wall thickness, and length must be carefully selected based on the heat exchanger's design parameters, fluid flow rates, and pressure drop considerations. Smaller tube diameters can provide higher heat transfer coefficients, but they may also lead to increased pressure drop. Additionally, thicker walls can enhance tube strength but may reduce heat transfer efficiency. Balancing these factors is essential to optimize the heat exchanger's performance.Corrosion Resistance

Corrosion is a major concern in heat exchanger applications, especially when dealing with aggressive fluids or environments. The choice of tube material should consider the corrosive nature of the process fluid and the operating conditions. Materials with excellent corrosion resistance, such as stainless steel or titanium, are preferred for applications where corrosion is a significant issue. Coatings or cladding can also be applied to enhance the corrosion resistance of the tubes.Thermal Conductivity

Thermal conductivity is another crucial factor to consider when selecting heat exchanger tubes. It determines the rate at which heat can be transferred between the fluids. Materials with high thermal conductivity, such as copper and copper alloys, facilitate efficient heat transfer, reducing the temperature difference across the heat exchanger. However, high conductivity materials may come with other limitations, such as lower mechanical strength or higher cost.Cost and Availability

Cost and availability are practical considerations in the selection of heat exchanger tubes. The chosen material should be cost-effective and readily available in the required specifications. It is essential to balance the desired material properties with the project budget and the long-term maintenance costs associated with the selected tubes. Availability of the chosen material in the market also ensures timely replacements or repairs if needed.Conclusion

when it comes to selecting heat exchanger tubes, several key factors must be considered to ensure optimal performance. Material selection, including stainless steel, carbon steel, copper alloys, and titanium, should be based on factors such as temperature, pressure, and fluid composition. Tube size and dimensions must be carefully chosen to balance heat transfer efficiency and pressure drop. Corrosion resistance is crucial, and materials like stainless steel and titanium excel in this aspect. Thermal conductivity affects heat transfer rates, and cost and availability considerations are essential. However, it's important to note that the topic of "A193 B6 bolts" appears unrelated to heat exchanger tubes and has not been addressed in this article.TAGS :

RECOMMENDED FOR YOU

Best Presale Crypto Launchpad Pays Your Travels

June 18, 2025

Top Signs of a Trustworthy Vehicle Shipping Company

June 17, 2025