Jersey Hijab: The Perfect Blend of Comfort and Style

January 13, 2025

Stainless steel coil tubing and SA 193 Gr B7 are essential components in various industries, particularly in construction, manufacturing, and oil and gas sectors. These materials offer unique properties that make them suitable for a wide range of applications. In this comprehensive guide, we will explore the characteristics, benefits, and applications of stainless steel coil tubing and SA 193 Gr B7, highlighting their significance in modern engineering and industrial practices.

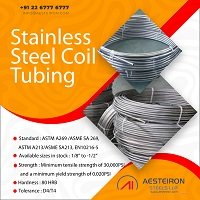

Stainless steel coil tubing is a type of tubing that is manufactured from stainless steel and wound into coils. This form of tubing is particularly advantageous in applications requiring long, continuous lengths of tubing, minimizing the need for joints and connectors. Stainless steel coil tubing is known for its excellent corrosion resistance, high strength, and durability.

Stainless steel coil tubing is utilized in a wide range of industries due to its versatile properties. Some of the key applications include:

In the oil and gas sector, stainless steel coil tubing is used for downhole and well-intervention applications. Its corrosion resistance and strength make it ideal for use in harsh subsurface environments, where it can withstand high pressures and corrosive substances.

Chemical processing plants use stainless steel coil tubing for fluid and gas transfer systems. The material's resistance to chemical corrosion ensures long-term reliability and reduces maintenance costs.

In medical and pharmaceutical industries, stainless steel coil tubing is employed for fluid delivery systems, including those used in laboratory and clinical settings. Its hygienic properties ensure that there is no contamination, maintaining the purity of the substances being transferred.

The food and beverage industry benefits from stainless steel coil tubing's hygienic properties, using it for fluid transfer systems, including those for dairy, beverage, and brewing processes. The material's ease of cleaning and resistance to food-grade chemicals make it an ideal choice.

SA 193 Gr B7 is a specification under the ASTM A193 standard, which covers alloy steel and stainless steel bolting materials for high-temperature or high-pressure service. Grade B7 refers to chromium-molybdenum alloy steel that is commonly used for manufacturing bolts, studs, and other fasteners.

SA 193 Gr B7 fasteners are used in a wide range of industries, particularly where high strength and temperature resistance are required. Some of the key applications include:

In the petrochemical industry, SA 193 Gr B7 bolts and studs are used in equipment such as reactors, heat exchangers, and pressure vessels. Their ability to withstand high temperatures and pressures makes them essential for these critical applications.

Power plants utilize SA 193 Gr B7 fasteners in turbines, boilers, and other high-temperature equipment. The material's strength and temperature resistance ensure reliable performance and safety in these demanding environments.

Manufacturers of heavy equipment, such as construction machinery and mining equipment, use SA 193 Gr B7 fasteners to ensure the structural integrity and durability of their products. The high strength of these fasteners provides the necessary support for heavy loads and harsh operating conditions.

In the construction of pipelines, especially those transporting high-temperature fluids, SA 193 Gr B7 fasteners are used to secure flanges, valves, and other components. Their resistance to thermal expansion and contraction helps maintain the integrity of the pipeline system.

Both stainless steel coil tubing and SA 193 Gr B7 fasteners offer exceptional durability, reducing the need for frequent replacements and maintenance. This enhances the overall lifespan of the systems in which they are used.

While the initial cost of stainless steel coil tubing and SA 193 Gr B7 fasteners may be higher compared to other materials, their long-term benefits, including reduced maintenance and replacement costs, make them a cost-effective choice for various applications.

The high strength and corrosion resistance of these materials ensure that they perform reliably in critical applications, contributing to the overall safety and efficiency of industrial operations.

The versatility of stainless steel coil tubing and SA 193 Gr B7 fasteners makes them suitable for a wide range of industries and applications. Their ability to perform under different conditions and requirements highlights their importance in modern engineering and industrial practices.

When selecting materials for specific applications, it is essential to consider the unique properties and requirements of the project. Stainless steel coil tubing and SA 193 Gr B7 fasteners offer numerous advantages, but understanding their specific benefits and limitations is crucial for making informed decisions.

Stainless steel coil tubing and SA 193 Gr B7 fasteners are indispensable in various industrial applications due to their exceptional properties, including corrosion resistance, high strength, and durability. Understanding the characteristics and applications of these materials enables industries to make informed decisions, enhancing the safety, reliability, and efficiency of their operations.

Whether in the oil and gas sector, chemical processing, power generation, or heavy equipment manufacturing, the use of stainless steel coil tubing and SA 193 Gr B7 fasteners ensures that systems operate smoothly and efficiently. By choosing the right materials for specific applications, industries can achieve long-term performance and cost savings, contributing to overall operational success.

TAGS :