Copper Nickel Pipes: A Versatile Solution for Industrial Applications

Introduction:

In the realm of industrial applications, the choice of piping materials is crucial to ensure durability, efficiency, and corrosion resistance. One such material that has gained significant recognition in recent years is copper nickel (CuNi). Copper nickel pipe have emerged as a versatile solution, offering a wide range of benefits for various industries. In this blog post, we will explore the key characteristics, applications, and advantages of copper nickel pipes.

Composition and Properties:

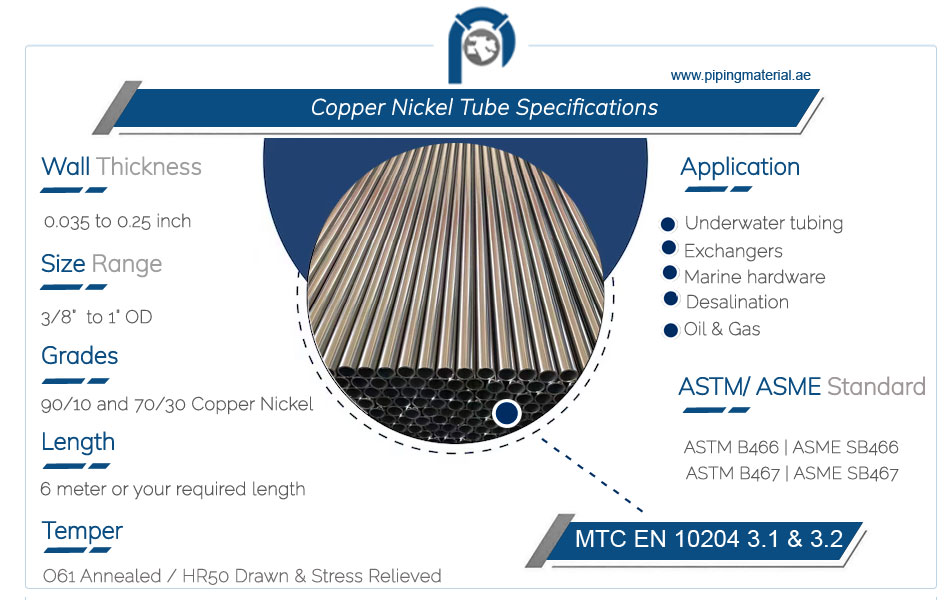

Copper nickel pipes are primarily composed of copper (Cu) and nickel (Ni), with small additions of other elements such as iron (Fe) and manganese (Mn). The most commonly used copper nickel alloy is C70600 (90/10 CuNi), containing 90% copper and 10% nickel. Another popular alloy is C71500 (70/30 CuNi), with 70% copper and 30% nickel. These alloys exhibit excellent resistance to corrosion, erosion, and biofouling, making them ideal for various environments, including seawater applications.

The properties of copper nickel pipes include:

- High resistance to seawater corrosion, erosion, and biofouling.

- Good mechanical strength and ductility.

- Excellent thermal conductivity.

- Low electrical resistance.

- Ease of fabrication and installation.

- Compatibility with other materials, such as carbon steel.

- Applications:

Copper nickel pipes find extensive use in a wide range of industries due to their unique properties. Some key applications include:

A. Marine and Offshore: Copper nickel pipes are widely employed in marine and offshore industries, including shipbuilding, desalination plants, offshore oil and gas platforms, and coastal power plants. They are used for seawater cooling systems, condensers, heat exchangers, and piping systems that require resistance to marine corrosion and biofouling.

B. Chemical Processing: In chemical processing plants, where corrosion resistance is vital, copper nickel pipes offer an excellent solution. They are utilized in the transportation of corrosive fluids, chemical reactors, and heat exchangers that handle aggressive chemicals.

C. Power Generation: Copper nickel pipes are extensively used in power generation facilities, such as thermal power plants and nuclear power plants. They are employed in heat exchangers, condensers, and steam generator tubing due to their ability to withstand high temperatures and corrosion caused by steam and water.

D. HVAC and Plumbing: Copper nickel tubes are also utilized in heating, ventilation, air conditioning (HVAC), and plumbing systems. Their high thermal conductivity ensures efficient heat transfer, while their corrosion resistance ensures longevity in plumbing applications.

- Advantages:

Copper nickel pipes offer several advantages that make them a preferred choice for various industries:

A. Corrosion Resistance: The inherent corrosion resistance of copper nickel pipes, especially in marine environments, significantly reduces maintenance costs and extends the service life of the piping system.

B. Reliability and Durability: Copper nickel pipes possess excellent mechanical strength, ensuring reliability and durability even under high-pressure conditions and harsh environments.

C. Heat Transfer Efficiency: With their high thermal conductivity, copper nickel pipes are highly efficient in heat transfer applications, resulting in enhanced system performance and energy savings.

D. Biofouling Resistance: The biofouling resistance of copper nickel pipes minimizes the growth of marine organisms, reducing the need for maintenance and improving overall system efficiency.

E. Compatibility: Copper nickel pipes can be easily welded or brazed, allowing for convenient installation. They are also compatible with other materials, such as carbon steel, facilitating connections and transitions within the piping system.

Conclusion:

Copper nickel pipes have emerged as a versatile and reliable solution for various industrial applications. Their corrosion resistance, durability, heat transfer efficiency, and biofouling resistance make them an ideal choice for marine, chemical processing, power generation, and HVAC systems. With their numerous advantages and compatibility with other materials, copper nickel pipes continue to be at the forefront of modern piping technology, ensuring efficient and long-lasting performance in diverse industries.

TAGS : Copper nickel pipe

RECOMMENDED FOR YOU

What are the advantages of the best infant car seats?

July 20, 2024